| The reactor is widely used in chemistry, materials, medicine and other industries.

In the chemical industry, the reactor is used in chemical synthesis, polymer chemistry, chemical reaction, material chemistry, dissolution, drying, degradation and so on. For example, high-pressure hydrogenation, catalytic reforming, nanomaterials synthesis and other processes require the use of reactors.

In the material industry, the reactor is widely used in the preparation of powder materials, thin film materials, coating materials, nanomaterials, energy materials and so on. For example, the preparation of battery materials, magnetic materials, optical glass materials will use the reactor.

In the pharmaceutical industry, the reactor is used for the synthesis of drugs, the preparation of new materials, the production of chemicals, intermediates and so on. For example, it can be used to prepare implantable medical devices, drug carriers, anti-cancer drugs, etc.

In addition, the reactor will also be used in food agriculture, university testing, biochemical pharmaceutical, alchemy industry and scientific experiments.

There are several reasons why the reactor needs to be cleaned:

Improve the cooling effect: cleaning the reactor can remove dirt, make the heat exchanger unblocked, water quality clear, at the same time can improve the heat transfer efficiency of the reactor, improve the cooling effect, ensure the product process, energy saving 10%-30% or more, so that the reactor safe and efficient operation.

Prolong the service life of the kettle: After cleaning, the kettle can prevent rust and scale, avoid corrosion and damage to the heat exchanger. After the addition of corrosion inhibitors, the corrosion rate of the equipment can be reduced by 90%, and the service life of the equipment can be doubled.

Saving energy consumption: cleaning the reactor can remove scale, prevent the formation of scale, reduce the cost of electricity or fuel while improving heat exchange efficiency, can improve the concentration ratio, reduce sewage discharge, improve the utilization rate of circulating water.

Cost saving: Uncleaned reactor will cause heat exchanger pipeline blockage, scaling, corrosion, overpressure shutdown, and even failure to scrap. Therefore, cleaning the reactor can save a lot of maintenance costs and avoid production loss.

Avoid the effect of residues on the reaction: the reaction kettle is easy to remain debris after use, and these residues will not only affect the capacity of the kettle, but also the composition of the reaction. Therefore, cleaning the reactor can remove these residues, ensure the unity of the reaction, reduce the impact of the impurity reaction, and reduce the probability of safety accidents.

In summary, the cleaning of the reactor is of great significance for improving equipment performance, ensuring product quality, reducing costs and improving safety.

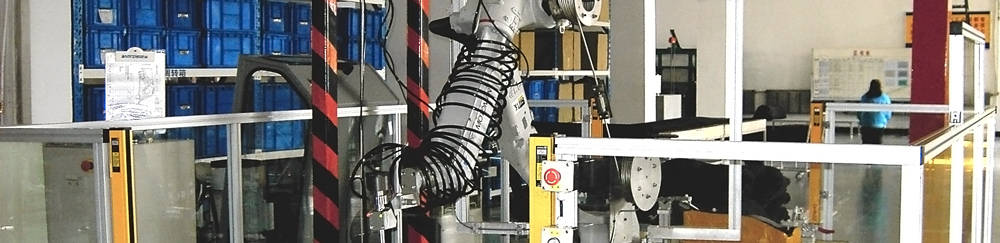

The automatic cleaning system for the reactor can choose the right pressure according to the scale composition and cleaning requirements, and use the kinetic energy of high pressure water jet to crush the hard scale on the inner wall of the reactor and the surface of the agitator, so as to completely peel and remove. The system can be customized according to the size of the reactor structure, which is more in line with the product needs to improve the cleanliness of the requirements.

In the cleaning process, the compound movement of the three-dimensional rotating nozzle and the telescopic rod makes the high-pressure water jet cover any position in the reactor, and finally complete the cleaning of the reactor. In addition, the high-pressure water unit can achieve constant pressure transportation of different jet flows, and the positioning telescopic device can realize fixed-point positioning cleaning by moving the position of the positioning switch.

In general, the automatic cleaning system of the reactor is a kind of integrated high pressure water jet, pipeline engineering, modern control system and other multidisciplinary technology cleaning device, can be customized according to actual needs, to completely clean the inner wall of the reactor and the hard scale on the surface of the agitator, improve the cleanliness of the goal.

|